Case Studies

Featured Case Study

Jaguar Landrover

Jaguar Land Rover has implemented the iLockerz ECO range of intelligent locker systems at its Halewood Plant, providing a secure, efficient solution for storing, recharging, vending, and managing a new fleet of 200 Honeywell CT45 devices with pistol grips.

This installation represents a major advancement in JLR’s commitment to technological innovation, operational efficiency, and intelligent asset management, ensuring critical mobile devices are always charged, traceable, and ready for use.

Metropolitan Police

The implementation of iLockerz PRO systems across the MPS estate has resulted in significant operational improvements.

West Midlands Police

Since installation, the iLockerz PRO system has redefined how the Roads Policing Unit manages critical equipment — setting a new benchmark for control, visibility and readiness.

Downeys Car Rental – Sixt

The implementation of iLockerz intelligent locker units drastically improved the customer experience, reducing the waiting time and allowing customers more freedom to tour.

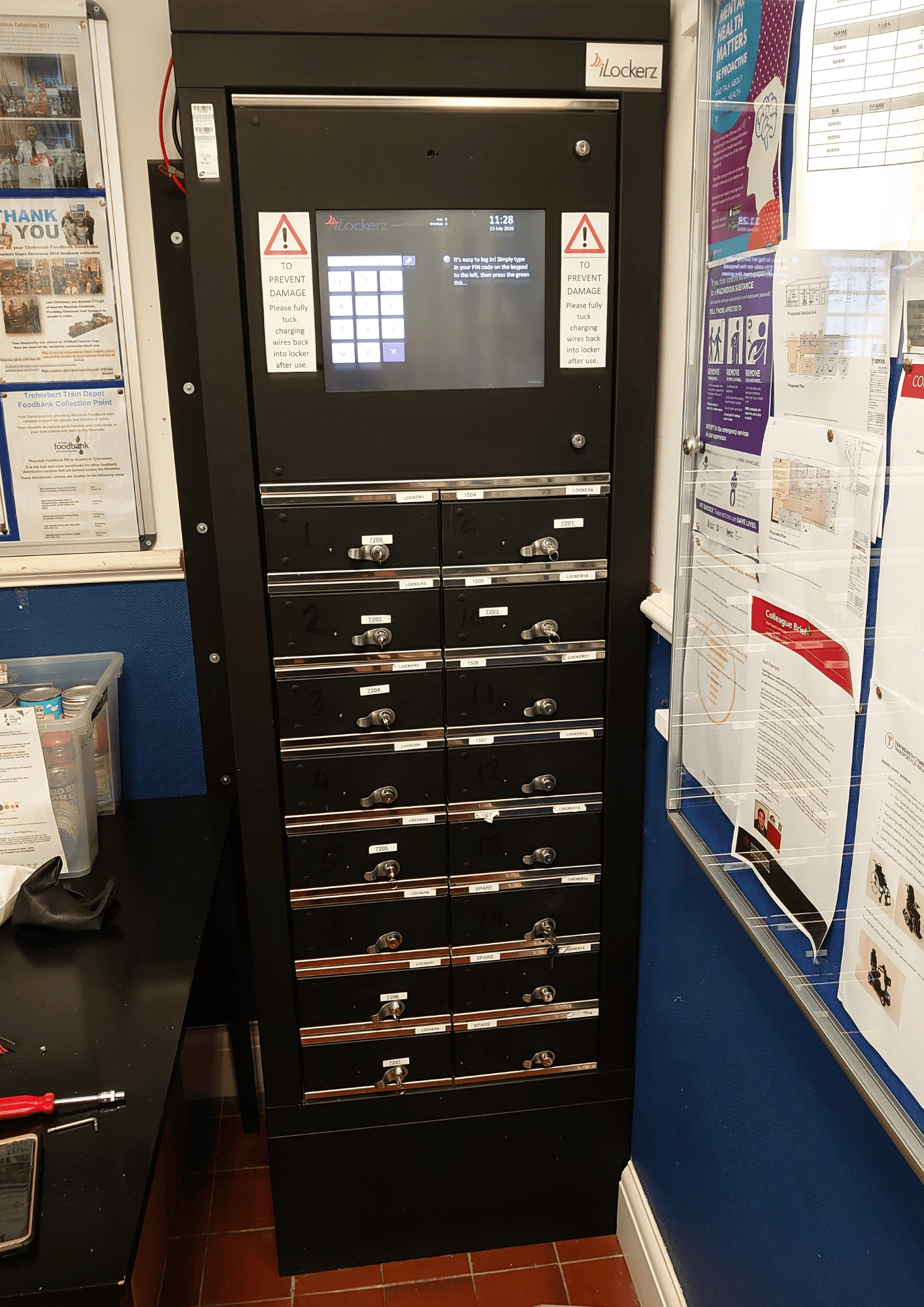

Arriva Trains Wales

The implementation of iLockerz mobile device management systems across Arriva Transport for Wales has delivered measurable operational improvements in both security and efficiency.

University of Sheffield

The installation of iLockerz electronic lockers at The University of Sheffield revolutionized its robotics program management. This system tackled key issues by ensuring secure and efficient robot storage and charging.

University College London

iLockerz delivers UCL a self-service storage and charging solution, with 9 systems across high-traffic student and library sites — enabling students and staff to securely stow valuables, charge devices, and move freely.

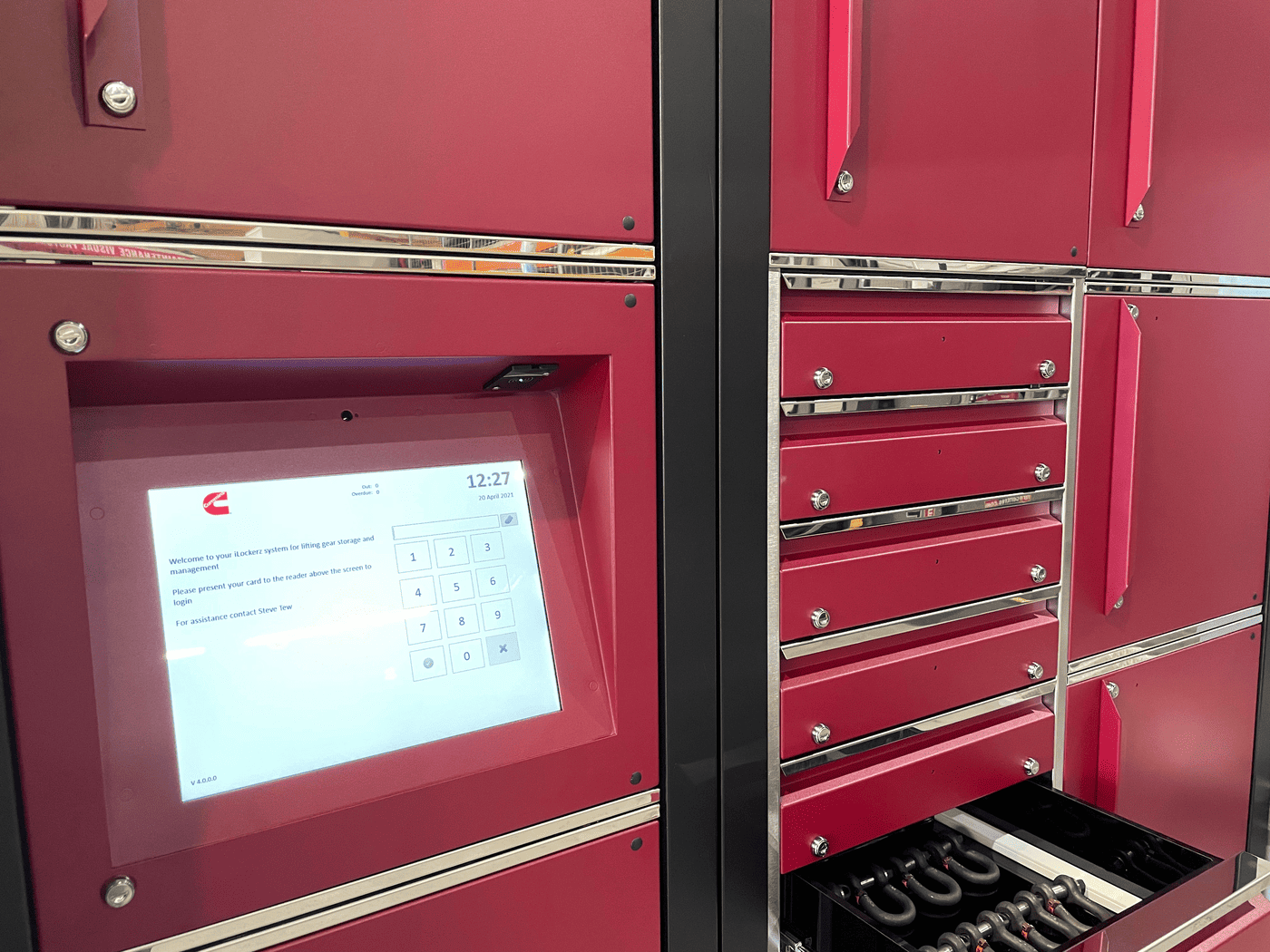

Cummins

iLockerz provides a solution for Cummins who faced challenges in efficiently managing its inventory of lifting gear, tools and other essential equipment.

Highlands College

iLockerz transforms learning environment and optimises resource management for Highlands College.

Wing Yip

iLockerz provides outstanding service while enhancing security and management of new devices across four distribution centres.

Caterpillar

Implementation of the iLockerz systems at Caterpillar’s Desford site and Perkins Engines resulted in substantial improvements in asset management and operational efficiency.

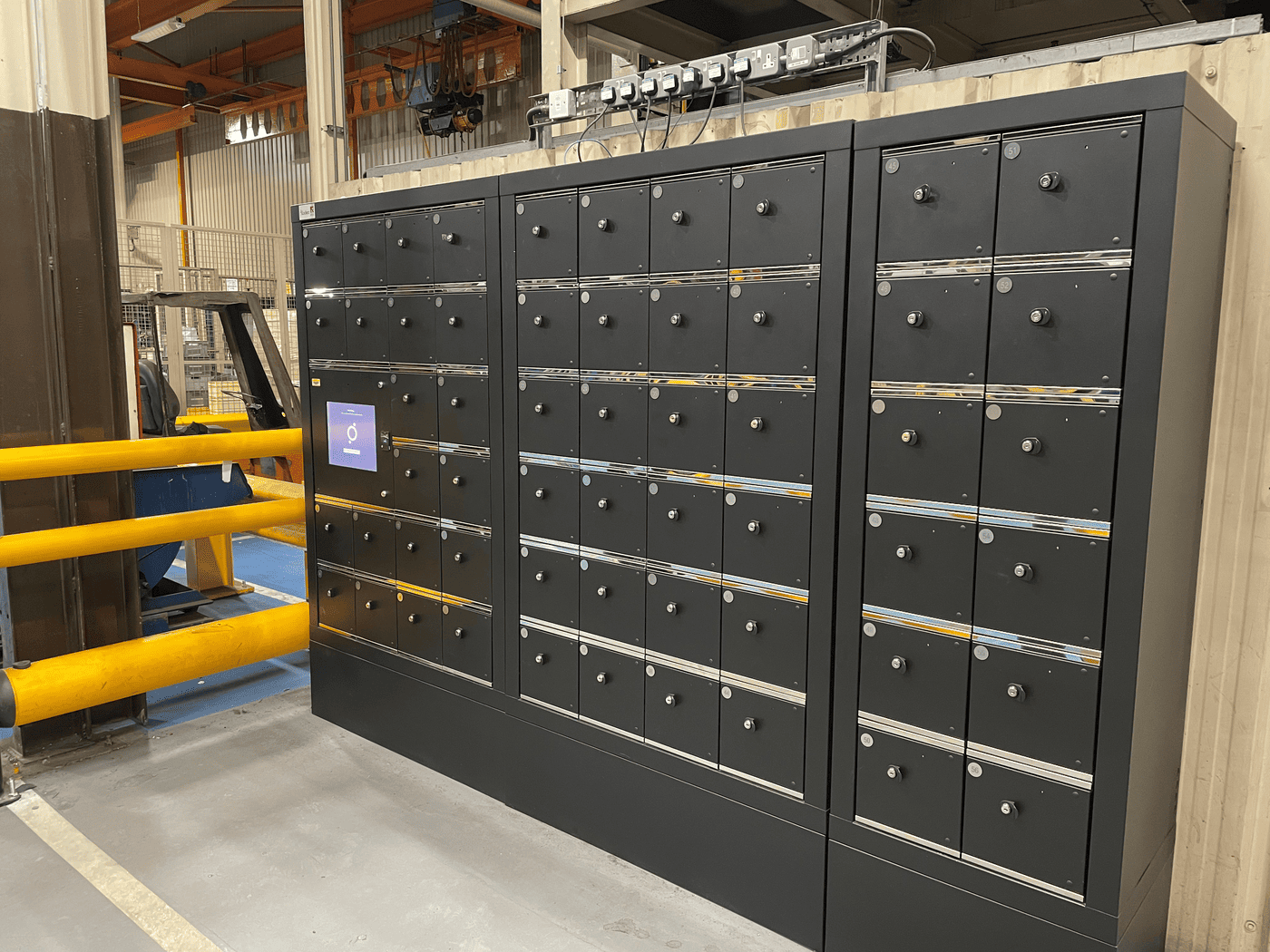

Jaguar Landrover

Since installing eight iLockerz systems, JLR has seen major improvements. The ‘LILO’ feature accelerates device issuance, ensuring quick access to fully charged devices while tracking usage and condition to promote accountability.

Oxford Brookes University

The implementation of iLockerz systems at Oxford Brookes has efficiently met the need for secure storage and flexible charging options, greatly improving the student experience on campus.

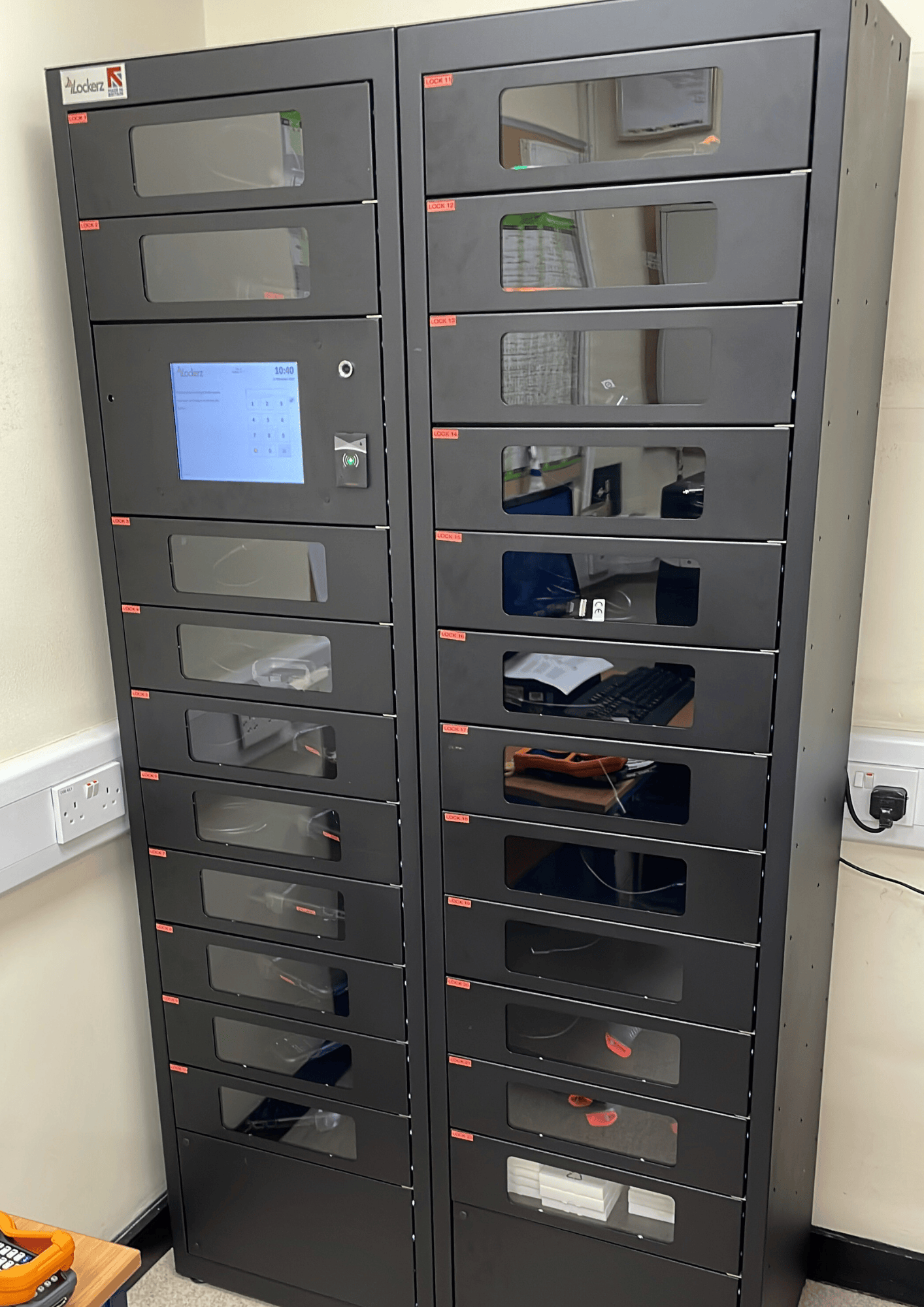

VOW Wholesale

Implementation of an iLockerz fully intelligent locker system improves equipment traceability and reporting in a busy warehouse environment.